The UK is a world leader in additive manufacturing, but it needs to continue to invest in innovation to stay ahead of the game.

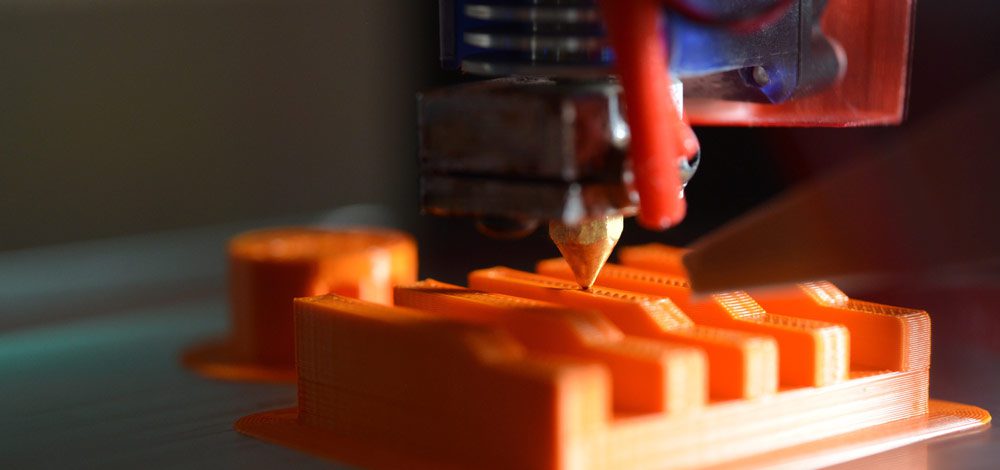

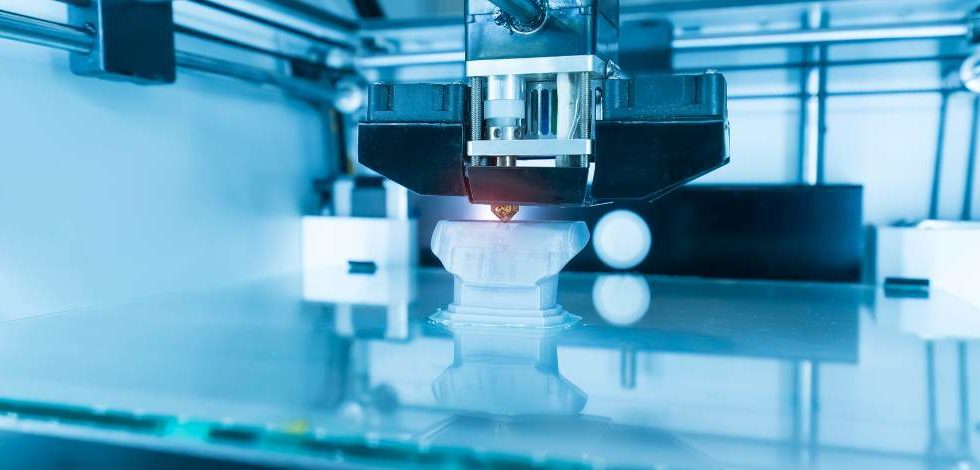

Additive manufacturing (AM), more commonly known as 3D printing, is the layer-wise manufacture of parts from computer files. For over twenty years, AM has played an essential role in supporting advanced R&D in a wide variety of sectors. Its primary role has been for prototyping and testing. However, over 50% of engineers who use AM produce end-use functional parts. This has been driven by many factors, including better awareness, rising productivity, improved quality, and the introduction of many new materials onto the market.

3D printing directly contributes over £500 million a year to the UK economy and has important spillover benefits to high-tech industries, which are more challenging to measure. It produces tooling for automotive composites and fixtures for bespoke machining jobs. More importantly, AM allows innovative companies to realise designs that would have been entirely impractical to manufacture just a few years ago. 3D-printed rocket engines, for example, may be used to launch rockets into space as soon as this year, with significant advantages over existing models.

Additive manufacturing’s head start in the UK

The UK is at the forefront of the growing industry, having been among the early adopters of the technology. This is good news, as the AM market is expected to grow 10% annually for the next five years. UK businesses now account for approximately 5% of the world’s additive manufacturing industry, and the government is hoping to increase this to 8% by 2025. The UK also is a major centre for academic research, with universities receiving tens of millions in funding annually. Early-stage research is thriving as a result.

Additive manufacturing is usually considered to be an expensive method of making things. This is true when manufacturing large numbers of simple parts, which can generally be produced more cheaply using other methods. The high costs are mainly caused by the purchase cost of AM machines, with high-end models costing several hundred thousand pounds.

The UK’s headstart in 3D printing puts it at a significant cost advantage. UK businesses already own a good number of machines outright. This level of capital investment makes high-value manufacturing such as 3D printing less vulnerable to offshoring relative to other manufacturing industries.

Even so, the cost of machines in real terms has decreased significantly over the last 20 years. When combined with various engineering and automation advances that have increased productivity, the cost of 3D printing is dramatically lower than ever before, which will lead to expanding uses of the technology.

Accelerated adoption

Historically, limited knowledge of the advantages and limitations of AM has been a significant barrier to its adoption. However, steady progress has been made in providing data, training, and learning resources to overcome this. AM is also increasingly taught during university engineering degrees. As designers become more familiar with AM, they discover more and more use cases. Often, the very first use of AM can “unlock” a company by building confidence. Adoption has accelerated in recent years, and this trend is set to continue.

Additive manufacturing is overcoming supply chain disruption

Over the last two years, the vulnerability of existing supply chains has been underscored by COVID-19, Brexit, and many other factors. When PPE and ventilator shortages gripped the nation, AM service providers rushed to help fill the gaps. These efforts were a mixed success, but one theme was consistent: 3D printers could be repurposed at the click of a mouse to help meet the new demand for certain parts. As a bonus, UK engineering companies benefit from faster delivery times when manufacturing occurs within the UK.

Adaptability is at the heart of AM’s offering, and this is hugely valuable when traditional supply chains are disrupted. Like other manufacturing businesses, the AM supply chain has been affected by a downturn in the civil aviation industry. However, the diversification of AM across multiple industries has allowed many companies to weather the storm.

Automation

Increasing automation in the industry is leading to steady improvements in cost-effectiveness. Software tools are becoming more capable and more integrated. Some machine makers integrate proprietary manufacturing software into commercial computer-aided design (CAD) packages. Other manufacturers have developed production planning software tools that plug into their enterprise resource planning (ERP) systems. These advances offer the potential for a step-change in terms of efficiency, planning and control.

Environmental considerations

Additive manufacturing is a mixed bag from an environmental standpoint. On the one hand, it is generally energy-intensive. Raw materials need to be made into tightly controlled feedstocks before manufacturers can use them in machines. These feedstocks can take the form of wire filaments, resins, or powders. Metal powders, for example, are usually made by atomisation, which involves blasting molten metal with an inert gas. This is an energy-intensive and wasteful process, as a significant proportion of the powder is unsuitable for use. Once the feedstocks have been manufactured, more energy is required in the 3D printer to convert the feedstock into a finished part. By the time the metal is made into a usable part, it has generally been melted several times and undergone multiple heat treatments. These all require energy.

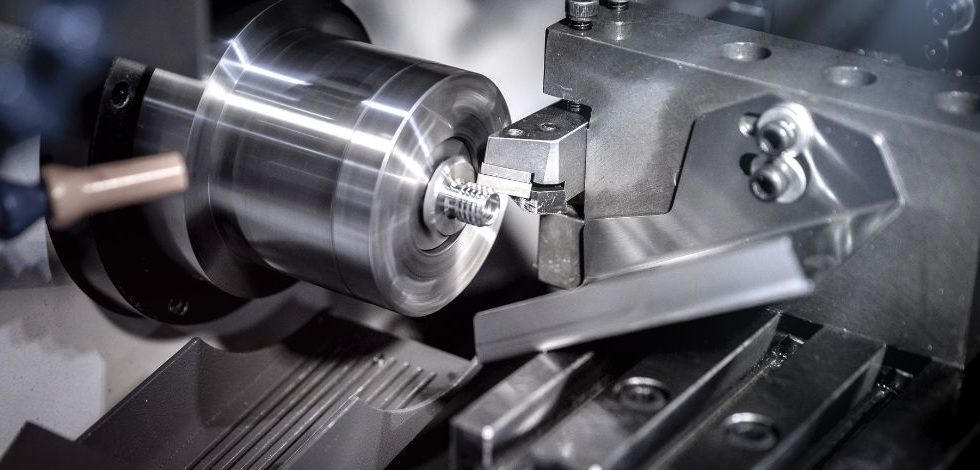

On the other hand, additive manufacturing wastes very little material during the manufacturing of the part itself. This is particularly important when dealing with expensive minerals or alloys which are difficult to cut. Parts can be printed to the required shape rather than wastefully cutting away material from a solid block. The spare powder can be reused and recycled, at least up to a point.

However, the primary environmental benefit of additive manufacturing is the opportunity to design more efficient machines. AM parts can be designed to weigh much less than their traditionally manufactured counterparts. This can save fuel and electricity when the parts are actually used. Manufacturers can use it to increase the performance of electric motors, heat exchangers, or even aeroplane engines. In doing so, they can use it to save vast amounts of energy over the product’s life, which outweighs the upfront energy use of the AM process itself.

Continuous innovation will help additive manufacturing

However, the UK’s 3D printing industry requires continuous innovation to remain competitive. Faster, larger machines are needed as engineers seek to use AM for more and more challenging projects. Engineers working in aerospace, automotive and oil and gas are becoming increasingly confident in the principles of the technology. But designers want high-quality data to back this up. There is still more to be done in terms of quality assurance, and statistical approaches may be required to control manufacturing processes better. Government incentives such as UKRI grants, R&D tax credits, and local growth funds will continue to play a large part in this. This investment will not only benefit companies specialising in AM but also a wide range of companies looking to exploit the engineering advances on offer.

No Comments