If the evolution of metallurgy and materials science began with the development of steelmaking in the first industrial revolution, it is accelerating with Industry 4.0. The field is witnessing the development of a whole raft of new and composite materials that promise to be lighter, stronger and more sustainable, among other advantages.

Plastics have long been a core packaging material and continue to provide an essential means of protecting vulnerable products, such as foodstuffs, along the supply chain, especially to consumers. However, increasing alarm at the damage plastics are causing to the environment has forced a major rethink by consumers, governments, NGOs and companies alike. Consumers, and retailers, have started to reject single-use plastics.

Mounting concern over climate change is reinforcing the drive across Europe and elsewhere to achieve a ‘circular economy’ that conserves precious natural resources, while reducing carbon emissions and other pollution. As pressure builds for this more sustainable, low-carbon environment, research into finding alternative materials is intensifying.

From steel to aluminium, plastics to biodegradable polymers, and carbon fibre reinforced plastics (CFRP) to graphene, man-made materials play, and will continue to play, essential roles in our everyday lives, though the cast is changing. Given the pressures to reduce our carbon footprint, materials engineering has to make an increasingly important contribution in manufacturing. It can help reduce energy consumption, through developments such as lightweighting, and the consumption of materials through better design.

Industry applications of advanced materials

While the aerospace industry has been in the vanguard of materials development and adoption, the automotive industry is coming up fast on the learning curve. Aircraft manufacturers have reduced the weight of their planes, using computer aided design (CAD) tools. They have also utilised light, yet strong materials, such as titanium and aluminium alloys, as well as hybrid materials like aluminium-sandwiched CFRP, in fuselage and aero-engine construction.

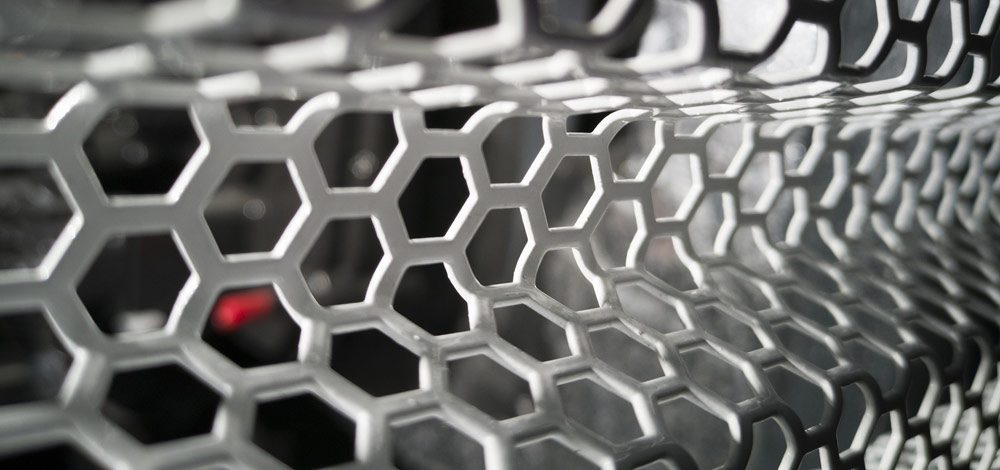

Carmakers have taken up the baton. While the cost of carbon fibre composites remain prohibitively expensive for the mass market, they are using increasing proportions of aluminium alloys in their vehicles as a substitute for steel. This reduces their overall weight, making cars more fuel-sufficient, without compromising rigidity and durability of construction, and safety. Jaguar Land Rover has been among the leaders in this field, incorporating more recycled aluminium from supplier Novelis in vehicles’ chassis to reduce their overall weight.

The shift away from petrol and diesel combustion engines to electric power for cars and trucks is fuelling the research into new types of batteries. Using advanced materials in their manufacture can make cells lighter and increase their lifespan. Breakthroughs in energy storage are also likely to depend on the outcomes of research into new materials. Toyota is investigating a solid-state battery using sulphide superionic conductors that could charge in seven minutes, making it ideal for cars.

The potential of graphene is particularly exciting. Made from single layers of carbon molecules, this material has many properties. It can provide lightweight, thin and flexible electric and photoelectric circuits in solar cells and many other devices and applications. These range from medical implants to chemical and industrial processes. In cars, for example, graphene could solve the problem of storing hydrogen fuel, or electrical charge through supercapacitors.

Meanwhile, the global impact of plastics has caused a shift towards more recyclable and biodegradable materials for the food and beverage industry. But much more work needs to be done in this area. Research is now focused on plant-based biopolymers, including polylactic acid (PLA) produced from sugarcane, as an alternative to plastics produced from petrochemicals. Most of the major drinks brands, including Coca-Cola and Innocent, that have traditionally used polyethylene terephthalate (PET) plastic drinks bottles, are investigating their use.

Advances in materials technology are therefore providing a gateway to new design opportunities – many yet to be discovered. They are likely to result in far more innovative products as well as assisting in the redesign of existing products to improve their functionality and performance.

As with the work by Airbus on fuselage design, scientists are learning lessons from nature itself and the way that organic species evolve. This process of ‘biomimicry’ holds promise for more sustainable materials in areas such as packaging. It is also behind developments of so-called ‘self-healing’ materials with a myriad of potential applications in manufactured goods.

For more trends in Industry 4.0, download your copy of “Re-tooling Industry for the Digital Age” here:

No Comments